Where you are now: Home»News Center»Company news

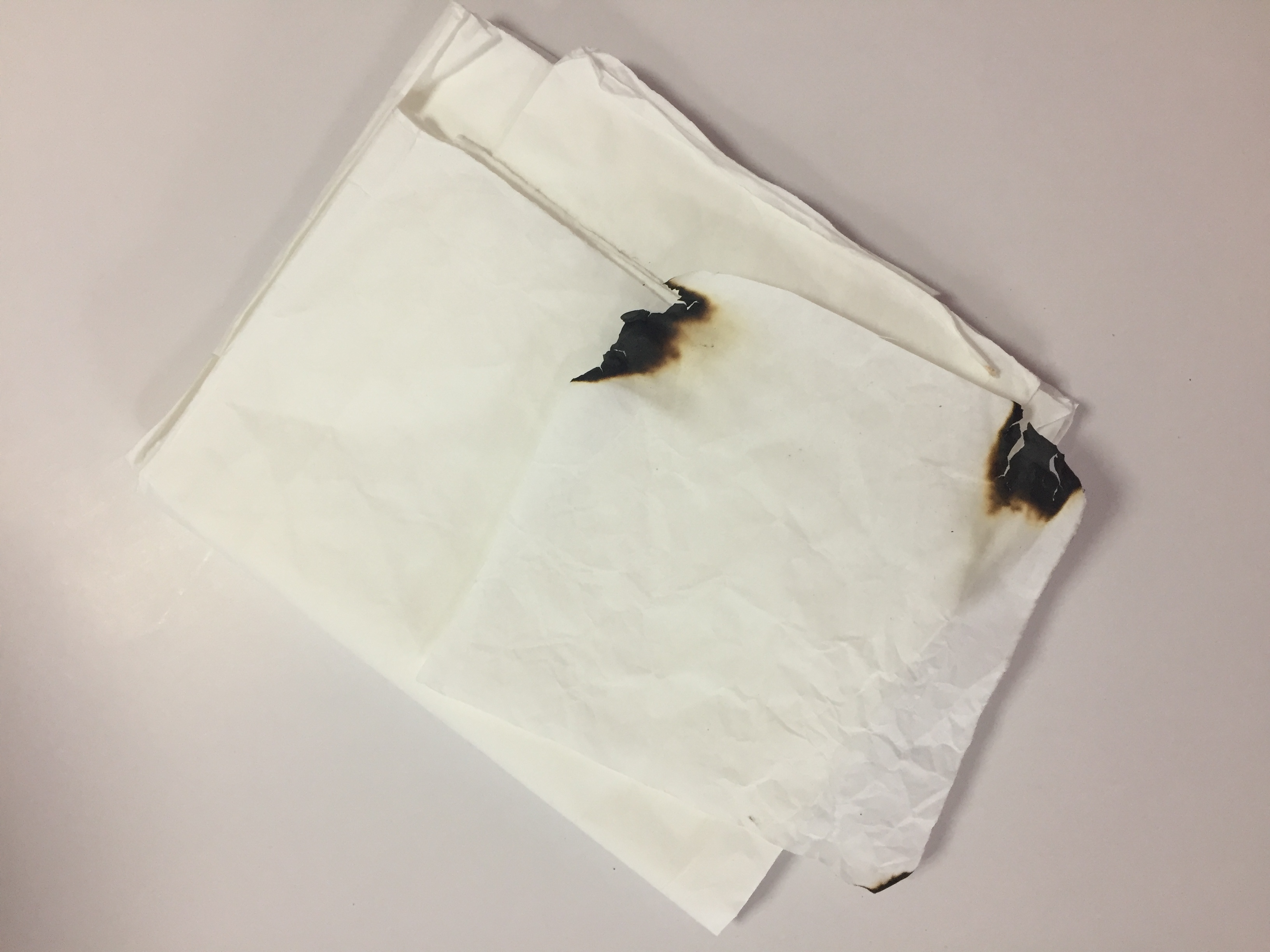

Nowadays, because awareness of fire safety is getting more and more attention, it is more and more important to make flam resisant paper. The production technology of fire resisant paper can be divided into the following categories:

1.Use non-combustible or non-combustible paper raw materials.

This kind of raw material contains asbestos, mineral wool, glass fiber and other inorganic fibers, through special papermaking technology, to make non-combustible or non-combustible paper.Of course, this kind of paper is restricted by the disadvantages of low strength, high cost and narrow use, and has not been widely used.

2.A Flame resisant that is insoluble in water.

In the pulping process, the flame retardant is added to the pulp with other paper additives.This method can disperse the flame retardant evenly in the paper, the flame retardant effect is good, the production time does not need to change the original paper equipment, the process also needs only small improvement.

The flame retardant used is generally insoluble in water.For example, aluminum hydroxide, a part of the ATH will be incorporated into the cellulose fiber body, and the other part will form a waterproof flame retardant product as a filler, so the dosage is very large (generally 30-60%).The flame retardant also has the advantages of whitening, improving thermal stability and printing performance.However, chlorinated paraffin and antimony trioxide flame retardant systems have limited their use due to their toxicity.

For water-soluble flame retardants, such as APP, the water content in the paper can be added at 5% to 10% of the water content, so as to avoid the loss of flame retardant.

3.Impregnating the original paper with flame retardant aqueous solution/water dispersion.

Due to the influence of paper thickness, the additive amount of flame retardant is usually 10-20g/m2, which is limited by means of method 2, and the impregned law is not subject to this limitation.This method is processed outside papermaking equipment, with a large range of changes, short processing time and convenient operation. It is suitable for all kinds of raw materials paper, decorative paper, wallpaper, building paper and so on.

The flame retardant dip treatment of paper products is similar to that of wood.The flame retardant is generally arranged into a water solution of 10% to 20%, adding a certain amount of osmotic agent, and after a period of time, it can be removed, dried and flat, and the flame retardant paper products are obtained.

The flame retardant treated with impregnation is mostly ammonium phosphate and water soluble polyphosphate.In recent years, guanidine and amino sulfonate are often used, but the paper is easy to absorb moisture, and the hand is not sensitive.

4.The flame retardant solution is coated on the surface of the paper.

This method is also called coating method, which is to use flame retardant aqueous solution or flame retardant dispersion brush to spray on paper surface.This method can save the amount of flame retardant, it is easy to operate, but it can only do surface flame retardant for thick paper, which is unfavorable for the overall flame retardant of the paper.

In the coating method, the flame retardant and adhesive can be used together to improve the strength of paper products and wear resistance.

5.Press into the flame retardant.

Add a certain amount of gelatine and precipitant into the sizing operation, sprinkle the flame retardant on the surface before applying it, and then press it into the paper.The adhesion of glue is limited, so this kind of flame-retardant treatment is not very good, and this method is only applicable to papermaking machine with glue press.

It can produce samples in a short time, which can be produced in small batches.At the same time, the flame retardant can be achieved with the minimum amount of flame retardant, and the extra cost is not high.

At present, the most by impregnation method and coating method are used to treat paper products of flame retardant, flame retardant paper with white and color on the market at present, white used more widely, mainly used in bar atmosphere away, robes, flame retardant paper can be customized package and plate specifications, in accordance with the requirements of customers